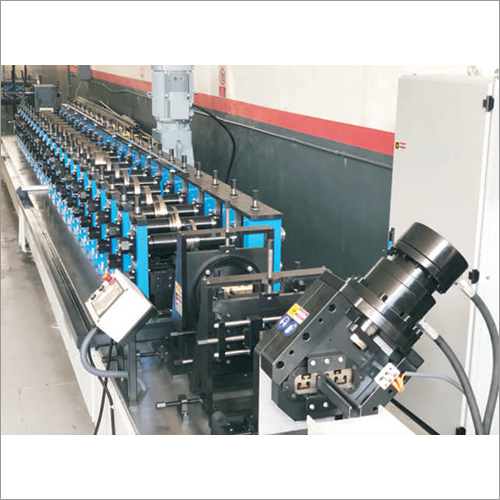

U Channel Roll Forming Machine

Price 4650000 INR/ Unit

MOQ : 1 Unit

About U Channel Roll Forming Machine

Entry Gate:- Entry gate will be provided for movement of sheet to roll former.

Main Base:

- The main base is MS fabricated structure and adequately ribbed to minimize the distortion

- It is accurately machined on top and bottom surfaces the threaded holes are made on the bed for positioning the stands.

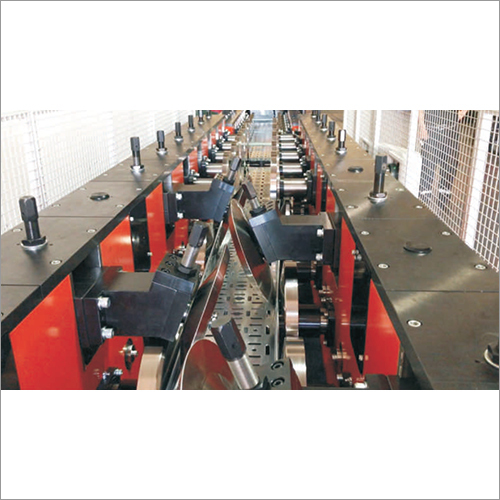

Mill stands (Station):

- The stands are mounted on the bed of the machine the line alignment can be easily done due to guideways arranged on the bed of the machine

- Each forming head consists of a fixed housing and sliding type out board housing

- The mill stands will be arranged to locate shafts mounted on taper bearings

- For the top shafts, the bearings are housed in the cartridge type bearing blocks

- The bottom shaft bearings are located in the bored machined in the housings

- The bottom arbors are fixed in position whereas the top arbors along with cartridge blocks could be raised or lowered in vertical guides machined in housings

Roll shafts:

- The roll shafts dia. 40mm will be manufactured from quality steel and will be keyed to locate tooling.

Drive:

- The drive to the roll former will be by means of a gearbox system

- The main drive will be provided by means of 2 HP motor

Tooling:

- One set of Tooling with EN31 grade will be from imported material suitable for your machine as standard supply

- The same is involved in operations like rough machining, keyway, rough profiling, bore grinding, profile machining and inspection with a final template for above.

Cutting Unit:

- Hydro. press 10 ton

- Motor: ABB

- Bearing: SKF

- Gearbox: ELECON

Additional Information:

- Pay Mode Terms: T/T (Bank Transfer)

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Roll Forming Machine Category

Stud Channel Roll Forming Machine

Price 2500000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Material : Metal

Automatic Grade : Automatic

Type : Stud Channel Roll Foaming Machine

Cable Tray Roll Forming Machine

Price 7500000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Material : Metal

Automatic Grade : Automatic

Type : Cable Tray Roll Forming Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free