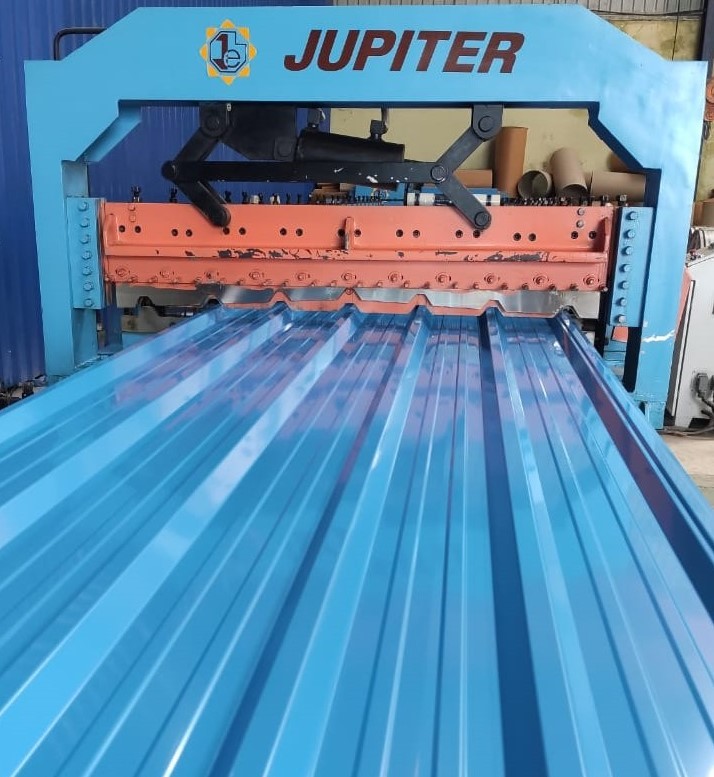

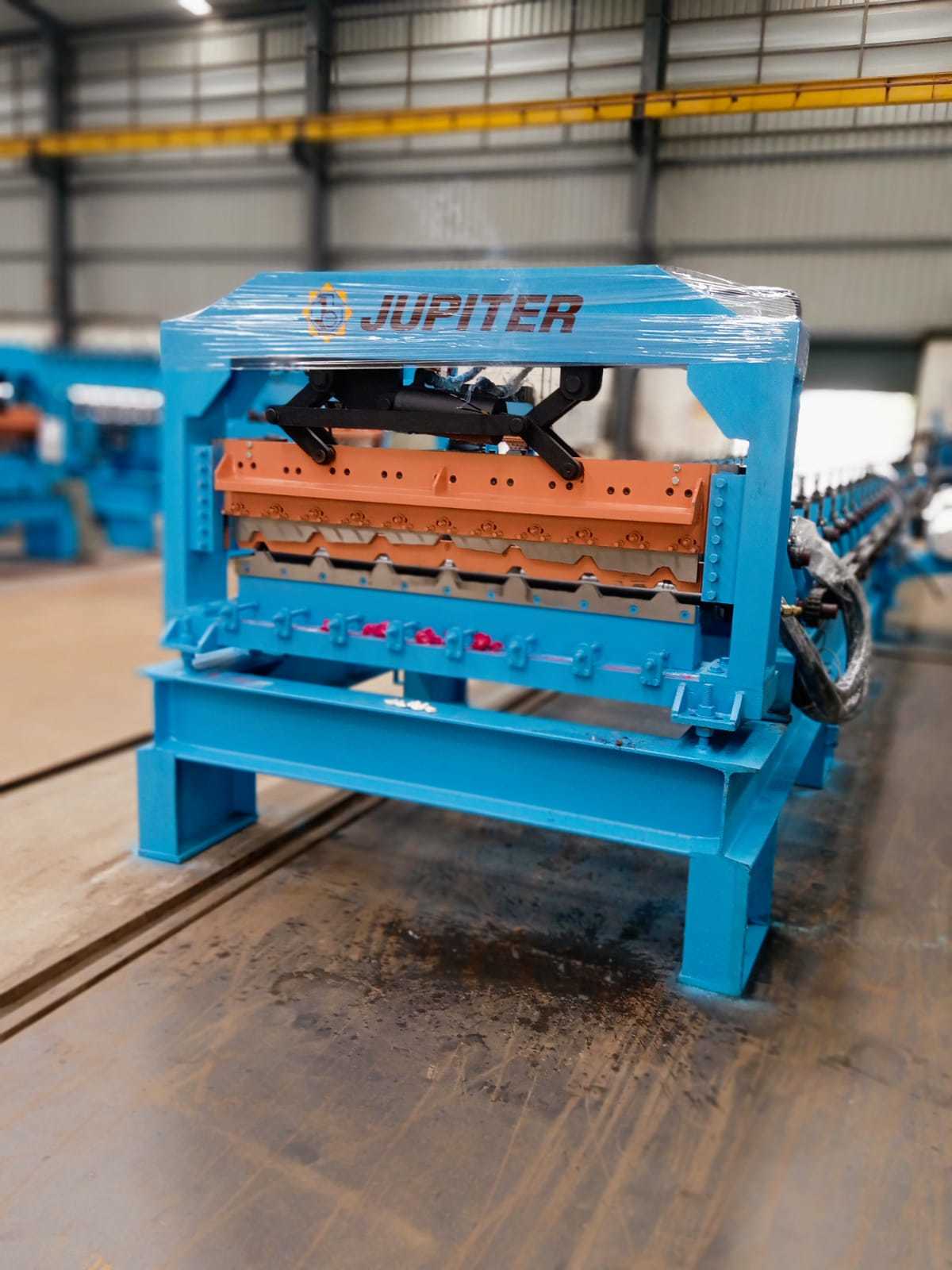

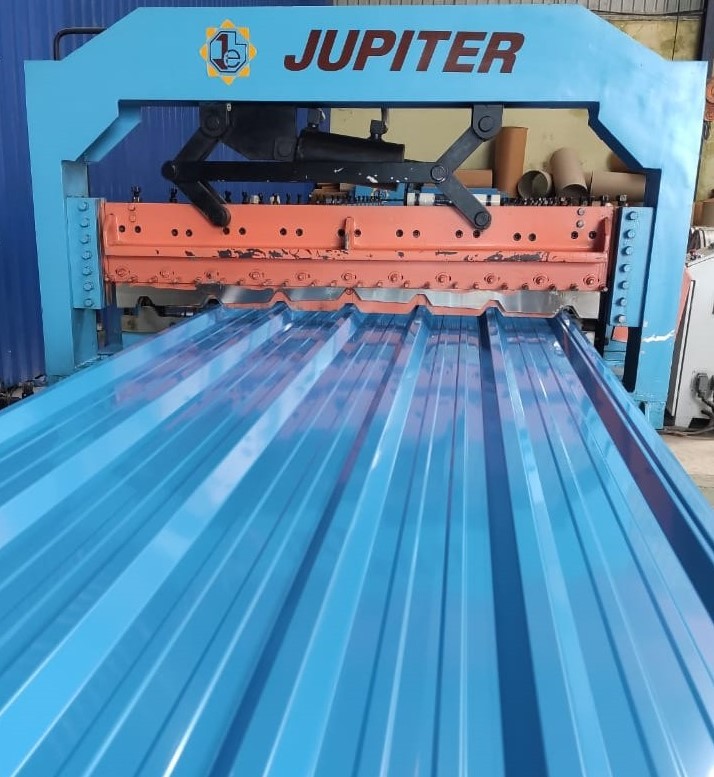

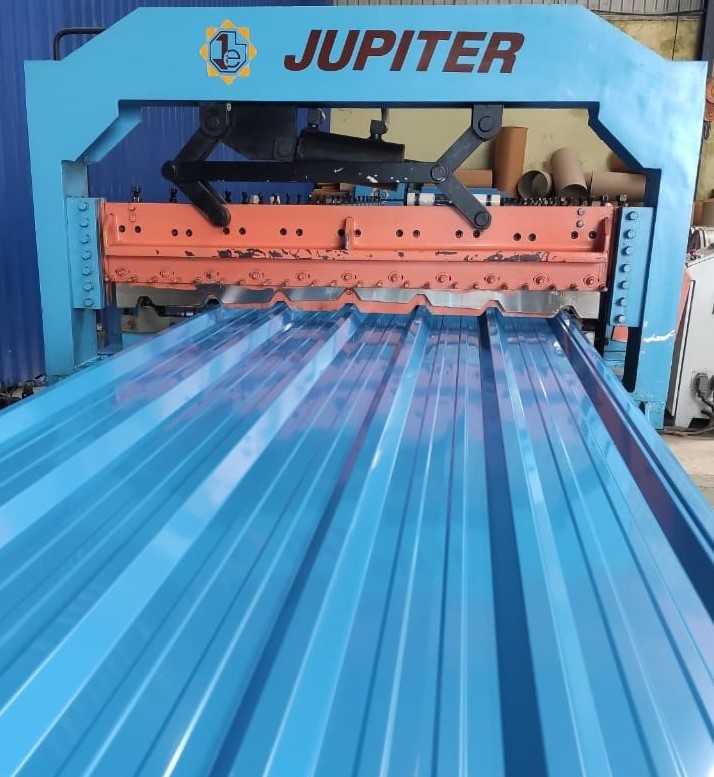

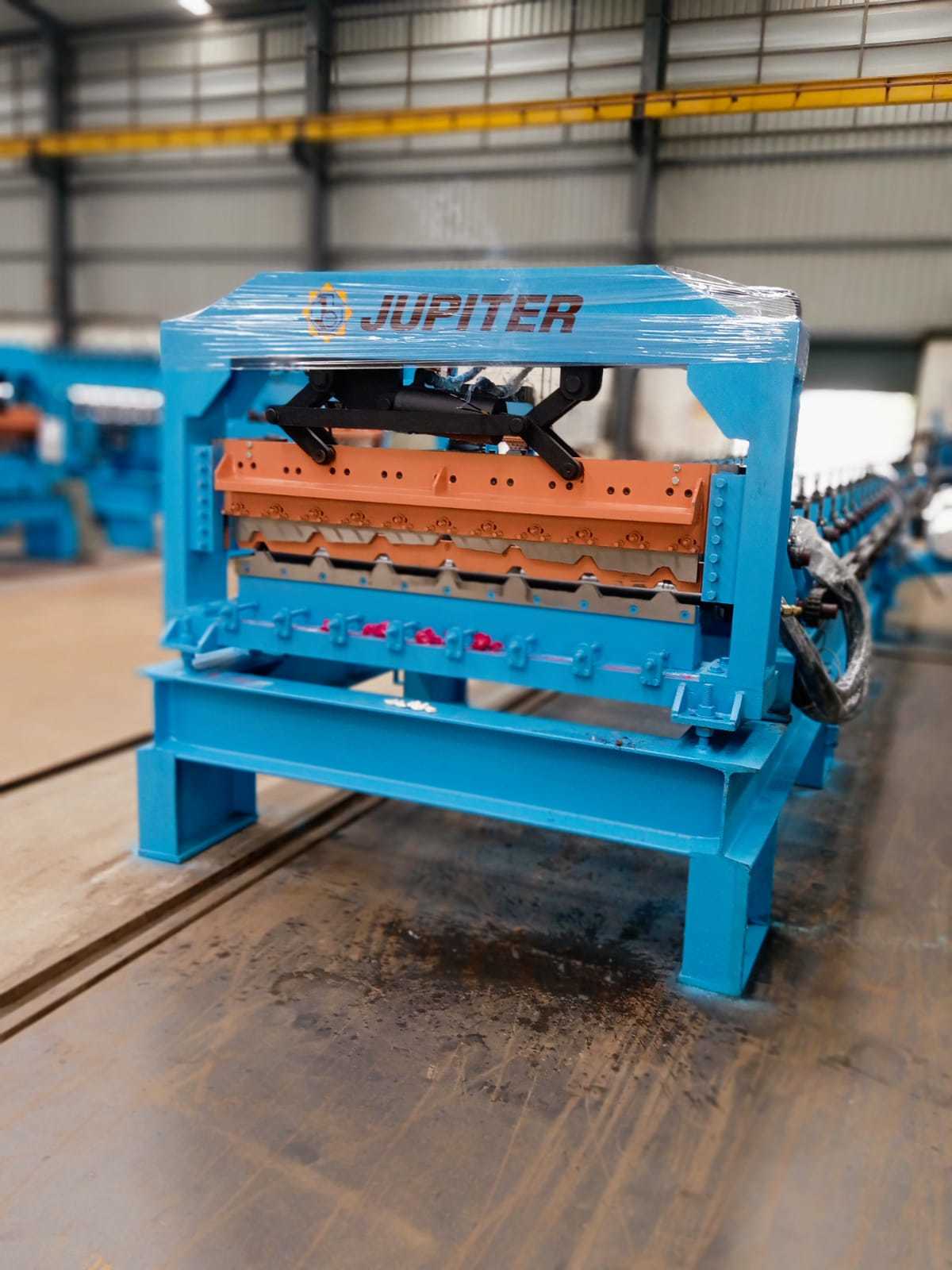

Roll Forming Line

Price 1100000 INR/ Unit

Roll Forming Line Specification

- Product Type

- Technology

- Power Source

- Electricity

- Operating Type

- Semi Automatic

- Power

- 230-440 Volt (v)

Roll Forming Line Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Week

- Delivery Time

- 30 Days

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

About Roll Forming Line

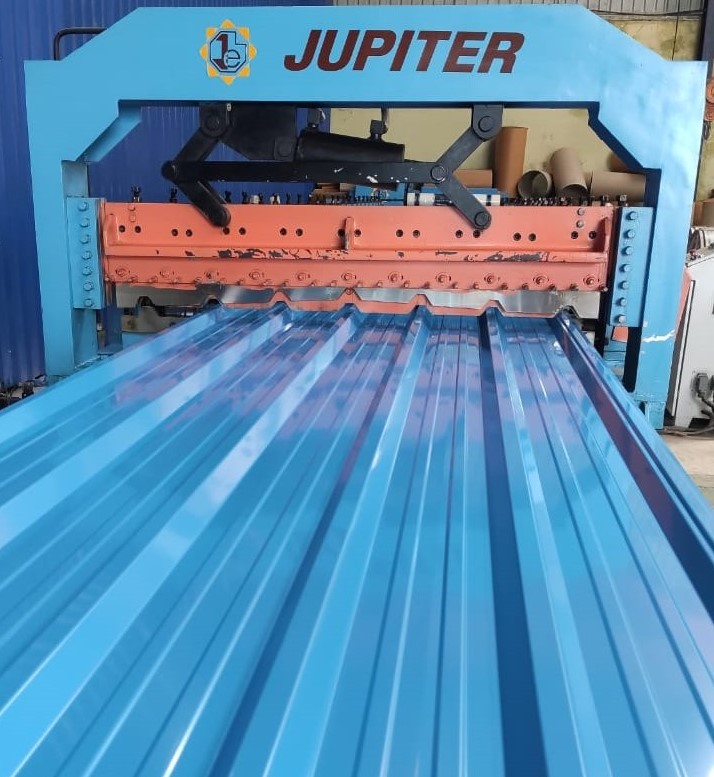

Roll forming is continuous bending operation in which a long strip of metal sheet (usually steel coils, like PPGI, PPGL, GI, PPGL, BGL, Aluminum etc.) passes through sets of rolls mounted on consecutives stand each set performing only an incremental part of the bend, until the desired cross-section profile is obtained. Roofing sheet roll forming machine consists of an automatic Decoiler feeding guide, roll forming unit, hydraulic cutter with PLC base control system.

We are involved in offering a wide array of color sheet making machine that is manufactured using high grade raw material and the latest technology with the set universal standards. These products are available in various specifications and can be customized as per variegated demands of our prestigious clients. Highest output speeds up you 30-40 meters per minute results in at least 10-15 times higher production. Maximum utilization of your investment practically any shape can be formed with uniform cross sections.

Any complicated Shape Profile can be formed on our roll forming. Accuracy and consistency in Shape & dimension can be achieved. Reduced delivery period to meet your production needs quickly. We develop Roll Forming Line & Roll Tooling on our most modern software up grated with our enriched experience and technology. We have in-house CNC & VMC machining centers to produce roll tools with our own quality control and check.

SPECIFICATION

| Number Of Forming Stations | 22 |

| Brand | jupiter |

| Automation Grade | Automatic |

| Job Thickness | 0.1-0.5 mm, 0.5-1 mm, 1-2 mm |

| Driven Type | Electric |

| Voltage required | 220V / 320V |

Product details

| Back Tension | Manually adjusted |

| Coil bore | 450 mm min, 510 mm max dia. |

| Coil weight | 3 MT Max |

| Coil width | 1450 mm |

| Horizontal distance between shafts | 190 mm |

| Mandrel movement | Manually adjusted |

| Maximum sheet thickness in G I Strips that can be formed | 1 mm |

| Maximum sheet width that can be formed | 1450 |

| Number of forming stations | 24 |

| Size of machine | 1600 x 800 x 1100 mm |

| Speed of the machine | 4mt/minute |

| Total HP for Line | 5 (ABB) |

| Vertical distance between shafts | 100 mm |

| Vertical station | 7 |

| Job Thickness | 0.1-0.5 mm,0.5-1 mm |

| Material | Steel |

| Cutting Type | Hydraulic |

| Automation Grade | Automatic |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Roof Accessories Machine Category

Roof Sheet Curving Machine

Price 2200000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Other, Roof Sheet Curving Machine

Operating Type : Automatic

Power Source : Electricity

Warranty : 1 Year

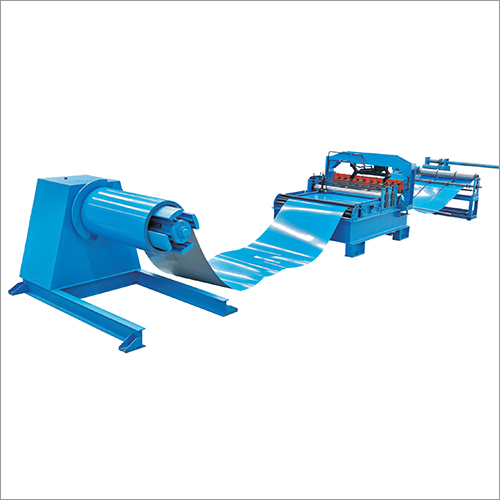

Baby Slitting Line Machine

Price 1100000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Baby Slitting Line Machine, Other

Operating Type : Automatic

Power Source : Electricity

Warranty : 1 Year

Press Break Machine

Price 550000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Press Break Machine, Other

Operating Type : Automatic

Power Source : Electricity

Warranty : 1 Year

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS