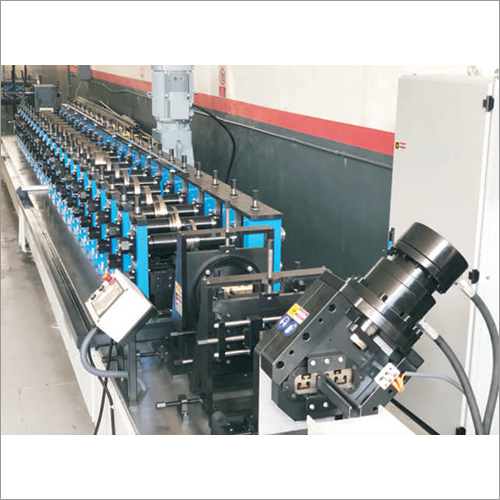

Double Decker Roll Forming Machine

Price 3650000 INR/ Unit

Double Decker Roll Forming Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T)

- Delivery Time

- 45 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Double Decker Roll Forming Machine

| Automation Grade | Automatic |

| Back Tension | Manually adjusted |

| Number of forming stations | 16 |

| Coil bore | 450 mm min,510 mm max dia. |

| Coil weight | 5 MT Max |

| Coil width | 1250 mm |

| Mandrel movement | Manually adjusted |

| Speed of the machine | 10 -14 mt / mint |

| Size of machine | 9500 x 1700 x 1100 mm |

| Maximum sheet thickness in CRCA Strips that can be formed | 1.2 mm |

| Horizontal distance between shafts | 500 mm |

| Total HP for Line | 8 |

| Maximum sheet width that can be formed | 1250 mm |

| Job Thickness | 0.5-1 mm, 0.1-0.5 mm, 1-2 mm |

Jupiter Enterprise manufacturing best quality Double Decker Roll Forming Machine in India also exporting worldwide. Most advanced yet simplest design and robust structure ensure precise performance, easy operation, and higher efficiency. These machines are available with 'manually' as well as 'automatically control' panel.

Entry Gate:

Entry gate will be provided for movement of sheet to roll former.

Main Base:

The main base is MS fabricated structure and adequately ribbed to minimize the distortion

It is accurately machined on top and bottom surfaces the threaded holes are made on the bed for positioning the stands.

Mill stands (Station):

The stands are mounted on the bed of the machine the line alignment can be easily done due to guideways arranged on the bed of the machine

Each forming head consists of a fixed housing and sliding type outboard housing

The mill stands will be arranged to locate shafts mounted on taper bearings

For the top shafts, the bearings are housed in the cartridge type bearing blocks

The bottom shaft bearings are located in the bored machined in the housings

The bottom arbors are fixed in position whereas the top arbors along with cartridge blocks could be raised or lowered in vertical guides machined in housings

Roll shafts:

The roll shafts dia. 70mm will be manufactured from quality steel and will be keyed to locate tooling.

Drive:

The drive to the roll former will be by means of a chain. The main drive will be provided by means of 10 HP motor

Tooling:

One set of Tooling with EN grade will be from imported material suitable for your machine as standard supply

The same is involved in operations like rough machining, keyway, rough profiling, profile machining and inspection with a final template for above.

Cutting Unit (Hydro):

Hydraulically operated power pack along with cutting die with 3 HP electrical.

Additional Information:

- Pay Mode Terms: T/T (Bank Transfer)

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Roll Forming Machine Category

Roll Forming Machine Manufacturer In Rajkot

Price 2550000 INR / Unit

Minimum Order Quantity : 1 Unit

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free